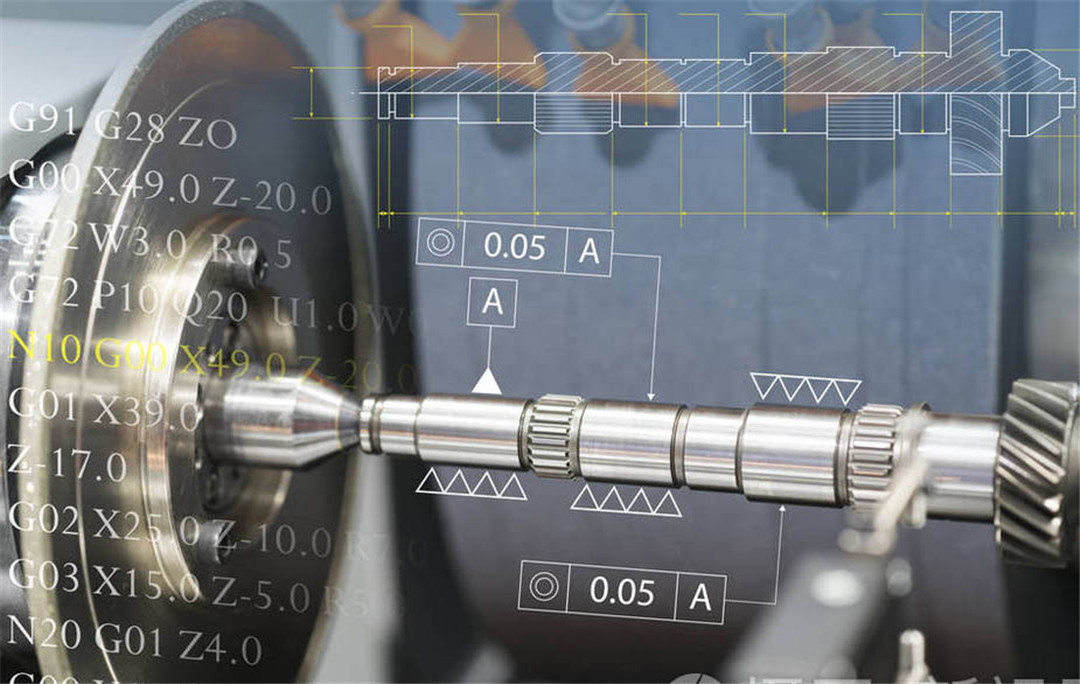

Waa maxay CNC Machining?

Mashiinka CNC waa habka wax soo saarka kaas oo ka faa'iideysanaya kontaroolada kombiyuutarada si ay ugu shaqeeyaan oo ay u maamulaan mashiinka iyo qalabka goynta si ay u qaabeeyaan alaabta kaydka-tusaale, birta, balaastigga, alwaax, xumbo, isku dhafan, iwm - qaybo gaar ah iyo naqshado.Iyadoo habka farsamaynta CNC uu bixiyo awoodo iyo hawlgallo kala duwan, mabaadi'da asaasiga ah ee geeddi-socodku waxay ahaanayaan kuwo isku mid ah oo dhan.

Habka mashiinka CNC wuxuu ku habboon yahay noocyo kala duwan oo warshado ah, oo ay ku jiraan baabuurta, hawada hawada, dhismaha, iyo beeraha, oo awood u leh inay soo saaraan noocyo kala duwan oo badeecooyin ah, sida muraayadaha baabuurta, qalabka qalliinka, matoorada diyaaradaha, gears iyo wixii la mid ah.Nidaamku waxa uu ka kooban yahay hawlgallada mishiinada kombuyuutarku gacanta ku hayo serveral kala duwan oo ay ku jiraan makaanikada, kiimikooyinka, korantada iyo hababka kulaylka - kuwaas oo ka saaraya mitirka lagama maarmaanka ah ee shaqada si loo soo saaro qayb ama badeecad gaar loo habeeyay.

Sidee buu u shaqeeyaa CNC Machining?

Habka aasaasiga ah ee mashiinka CNC waxaa ka mid ah marxaladaha soo socda:

Dejinta qaabka CAD

U beddelashada faylka CAD barnaamijka CNC

Diyaarinta mashiinka CNC

Fulinta hawsha mishiinada

Marka nidaamka CNC la hawlgeliyo, goynta la doonayo waxaa lagu habeeyaa software-ka waxaana lagu tilmaamaa qalabyada iyo mashiinnada u dhigma, kuwaas oo fuliya hawlaha cabbirka sida loo cayimay, si la mid ah robot-ka.Barnaamijyada CNC, koronto-dhaliyaha koodhka ee nidaamka nambarada ayaa inta badan u qaadan doona in hababku yihiin kuwo aan cillad lahayn, inkastoo ay suurtogal tahay khaladaad, taas oo ka weyn mar kasta oo mashiinka CNC lagu tilmaamo in la gooyo in ka badan hal jiho isku mar.Meelaynta qalabka ee nidaamka xakamaynta tirada waxaa lagu qeexay taxane taxane ah oo loo yaqaan barnaamijka qaybta.

Mashiinka xakamaynta tirada, barnaamijyada waxaa lagu geliyaa kaadhadhka feerka.Taas bedelkeeda, barnaamijyada mashiinnada CNC waxaa lagu quudiyaa kombiyuutarada iyada oo loo marayo kiiboodhka yaryar.Barnaamijyada CNC waxa lagu hayaa xusuusta kombiyuutarka.Koodhka laftiisa waxa qoray oo tafatira barnaamij-yaqaano.Sidaa darteed, nidaamyada CNC waxay bixiyaan awood xisaabeed aad u ballaaran.Waxa ugu wanagsan, nidaamyada CNC sinaba ma aha kuwa fadhiid ah sababtoo ah dardargelin cusub ayaa lagu dari karaa barnaamijyadii hore u jiray iyada oo loo marayo kood dib loo eegay.

Noocyada CNC Machining Operations CNC leexashada

CNC Turning waa hab-raac makiinadeed kaas oo ka shaqeeya qalab goynta hal-dhibcood ah si looga saaro walxaha wareegtada shaqada.Awoodaha hawlgalka ee habka rogidashada waxaa ka mid ah caajis, weji, jeexid, iyo jaridda dunta.Mashiinnada laashka, qaybo ka mid ah waxaa loo gooyaa jihada wareeg ah oo leh qalab la tilmaami karo.Iyada oo la adeegsanayo tignoolajiyada CNC, jarista ay adeegsadaan lathes waxaa lagu fuliyaa si sax ah oo xawaare sare leh.Lathes CNC waxaa loo isticmaalaa in lagu soo saaro naqshado adag oo aan suurtagal ahayn noocyada gacanta lagu maamulo ee mishiinka.Guud ahaan, hawlaha kantaroolka ee mashiinnada CNC-du ay maamulaan iyo lathes ayaa la mid ah.Sida warshada CNC, suufka waxaa hagi kara G-code ama kood gaar ah oo gaar ah.Si kastaba ha noqotee, inta badan xargaha CNC waxay ka kooban yihiin laba faas - X iyo Z.

CNC Milling

CNC Milling waa hab-raac makiinadeed kaas oo shaqaaleeya wareegtada aaladaha goynta dhibco badan si looga saaro walxaha shaqada.Mishiinnada CNC waxay awood u leeyihiin inay ku shaqeeyaan barnaamijyo ka kooban lambar iyo xaraf ku salaysan oo haga qaybaha masaafo kala duwan.Barnaamijyada loo isticmaalo mishiinka wax-shiidka waxa ay ku salaysnaan kartaa Gode ama luuqad gaar ah oo la soo saaray koox keenaysa, m-cos-ka aasaasiga ahi waxa uu ka kooban yahay nidaamka saddex geesoodka ah (X, Y iyo Z), in kasta oo mishiinnada cusubi ay qaadi karaan saddex faasas oo dheeraad ah.Awoodaha hawl-shiidka ee geeddi-socodka wax-shiidka waxa ka mid ah-wax-shiid--jarjar-gacmeed-gacmeed, sagxadaha fidsan iyo dalool-hoosaadka hoose oo fidsan oo geliya godad-shaqo-iyo-wax-shiid-shiidid-wareeg-jaridda godadka qoto dheer, sida boosaska iyo dunta, oo geliya workpiece.

5 Mashiinka dhidibka

Mashiinka dhidibka 3, 4, ama 5 waxaa lagu qeexay tirada jihooyinka kaas oo qalabka goynta u dhaqaaqi karo, tani waxay sidoo kale go'aaminaysaa awoodda mashiinka CNC si uu u guuro workpiece iyo qalab.3-axis machining centers waxay dhaqaajin kartaa qayb ka mid ah jihooyinka X iyo Y, qalabkuna kor iyo hoos buu u socdaa dhinaca Z- dhidibka, halka 5-ta dhidibka xarunta, qalabku uu ka gudbi karo xadhkaha xariiqda ee X, Y iyo Z iyo sidoo kale wuxuu ku wareegaa faasasyada A iyo B, taas oo ka dhigaysa gooyuhu inuu u soo dhowaan karo shaqada jiho kasta iyo xag kasta.5 dhidibkii machining waa ka duwan yahay machining 5-dhinac ah.Sidaa darteed, 5 dhidibada CNC adeegyada machining u ogolaanaya ininfinte suurto gal ah ee qaybaha mashiinada.Mashiinka dusha sare ee Hook, makiinada qaabka aan caadiga ahayn, makiinada godan, feedhitaanka, goynta qallafsan, iyo shayaadyo gaar ah oo dheeraad ah ayaa la jiri kara 5 dhidibeedka CNC adeegga.

Mashiinka Nooca Swiss

Mashiinka nooca Swiss waxaa loogu yeeraa makiinadaha nooca Swiss-ka ah ama suufka toosan ee Swiss, waa warshad sax ah oo casri ah oo soo saari karta qaybo aad u yaryar si degdeg ah oo sax ah.

Mishiin Swiss ah wuxuu ku shaqeeyaa quudinta kaydka baarka iyada oo loo marayo buunshiyaha hagaha, kaas oo si adag u taageera walxaha marka ay ku quudiyaan aagga qalabka mashiinka.

Marka la barbar dhigo dhogorta toosan ee dhaqameed ee nooca Swiss-ka ah ayaa si gaar ah awood u leh inay soo saaraan qaybo aad u yaryar oo sax ah oo xawli ku socda.Isku dhafka saxda ah ee saxda ah iyo mugga wax soo saarka sare wuxuu ka dhigayaa mashiinnada Swiss qayb muhiim ah oo ka mid ah dukaamada kuwaas oo ay tahay inay soo saaraan mug weyn oo yar yar iyo qaybo adag oo yar oo khalad ah.

Alaabta lagu isticmaalo Codsiga Makiinada ee CNC

Iyadoo ay jiraan waxyaabo badan oo kala duwan oo aad ku isticmaali karto mashiinka CNC, qalabka ugu badan ee la isticmaalo waa:

Aluminium Alloys

● Al 6061-T6

● Al6063-T6

● Al7075-T6

● Al5052

● Al2024

Aloysyada birta aan-ahmaah ahayn:

● Birta aan la taaban karin 303/304

● Birta aan la taaban karin 316/316L

● birta aan-dhalin 420

● birta aan-dhalin 410

● birta aan-dhalin 416

17-4H

● birta aan-xawaaraha lahayn 18-8

Caag:

POM (Delrin), ABS (Acrylonitrile Butadiene Styrene)

● HDPE, Naylon (PA), PLA, PC (Polycarbonate)

PEEK (Polyether Ether Ketone)

● PMMA (Polymethyl Methacrylate ama Acrylic)

PP (Polypropylene)

PTFE (Polytetrafluoroethylene)

Copper & Alloys Naxaasta:

● Copper 260

● Copper 360

● H90, H80, H68, H62

Aloysyada birta kaarboon:

● Birta 1018, 1024, 1215

● Birta 4140, 4130

● Birta A36…

Alloys Titanium:

● Titanium (Fasalka 2)

● Titanium (Fasalka 5)

Dhamaystirka CNC iyo Ikhtiyaarada ka-baahsanaanta

Dhamaystirka dusha sare waa tallaabada ugu dambeysa ee mashiinka CNC.Dhamaystirka waxaa loo isticmaali karaa in meesha laga saaro cilladaha bilicda, hagaajinta muuqaalka alaabta, bixinta xoog iyo caabin dheeri ah, hagaajinta dhaqdhaqaaqa korantada, iyo wax ka badan.

● Sida Machined

● Anodizing (Nooca II & Nooca III)

● Daahan budada ah

● Korontada

● Usku qarxin

● Turun-tuur

● Kalsoonida

● Filim kiimiko ah (Dahaarka Beddelka Chromate)

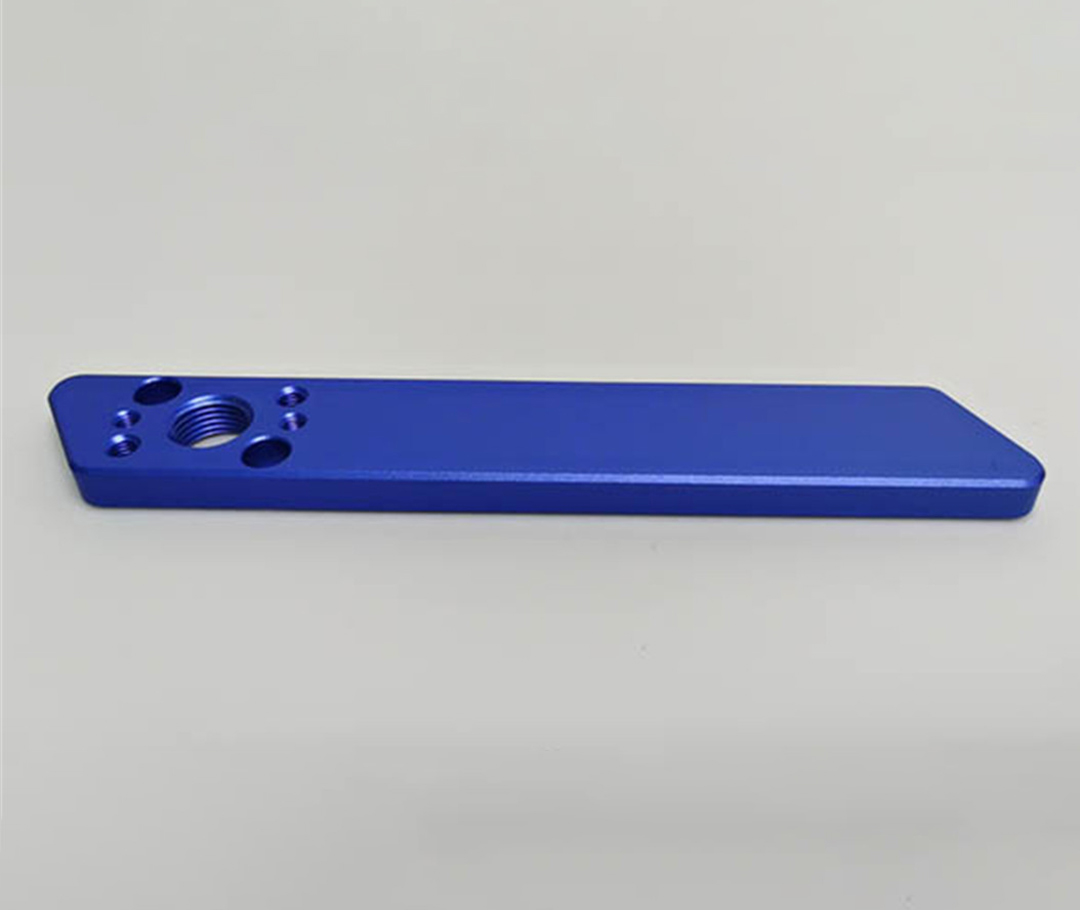

Eeg qaar ka mid ah Tusaalooyinka Qaybahayada CNC Machiined

Dareenka Dalbashada Qaybaha Mashiinnada CNC ee Mashiinnada Xiddigaha

Isbeddel degdeg ah:Jawaab celin degdeg ah oo loogu talagalay RFQ gudaha 24 saacadood.Isticmaalka mashiinada CNC ee ugu dambeeyay, Star Machining waxay soo saartaa qaybo aad u sax ah, oo degdeg ah qaybo ka mid ah sida ugu dhakhsaha badan 10 maalmood.

Saxnaanta:Star Machining waxay bixisaa doorashooyin dulqaad oo kala duwan si waafaqsan heerka ISO 2768 iyo xitaa aad u adag sida codsigaaga.

Xulashada agabka:Ka dooro in ka badan 30 bir iyo walxo balaastig ah sida aad u baahan tahay.

Dhammaadka gaarka ah:Ka dooro noocyo kala duwan oo o dhammays ah oo ku yaal qaybo adag oo bir ah iyo balaastig ah, oo loo dhisay si qeexan qaabeynta saxda ah.

Khibrad:Injineeradayada khibrada leh ee hodanka ah ayaa ku siin doona jawaab celin degdeg ah DFM.Mashiinnada Xiddigaha waxay leeyihiin in ka badan 15 sano oo maarayn wax soo saar ah.Waxaa jira kumanaan shirkadood iyo mashruucyo aan u adeegnay warshado kala duwan, in ka badan 50 waddan oo aan soo dirnay.

Xakamaynta tayadaWaaxdayada QA waxay fulisaa dammaanad tayo leh oo xooggan.Laga soo bilaabo alaabta ilaa rarida alaabta ugu dambeysa waxaan ku sameynaa kormeer adag oo leh heerka caalamiga ah.Qaybaha qaarkood waxaanu samaynaa kormeer buuxa sida codsiga macmiilka.

Gaadhista Degdega ah:Marka laga reebo side loo qoondeeyay, waxaanu sidoo kale haysanaa wakiilkayaga DHL/UPS iyo soo gudbiyaha kaas oo ku soo rari kara qaybahaaga si degdeg ah iyo qiimo macquul ah.